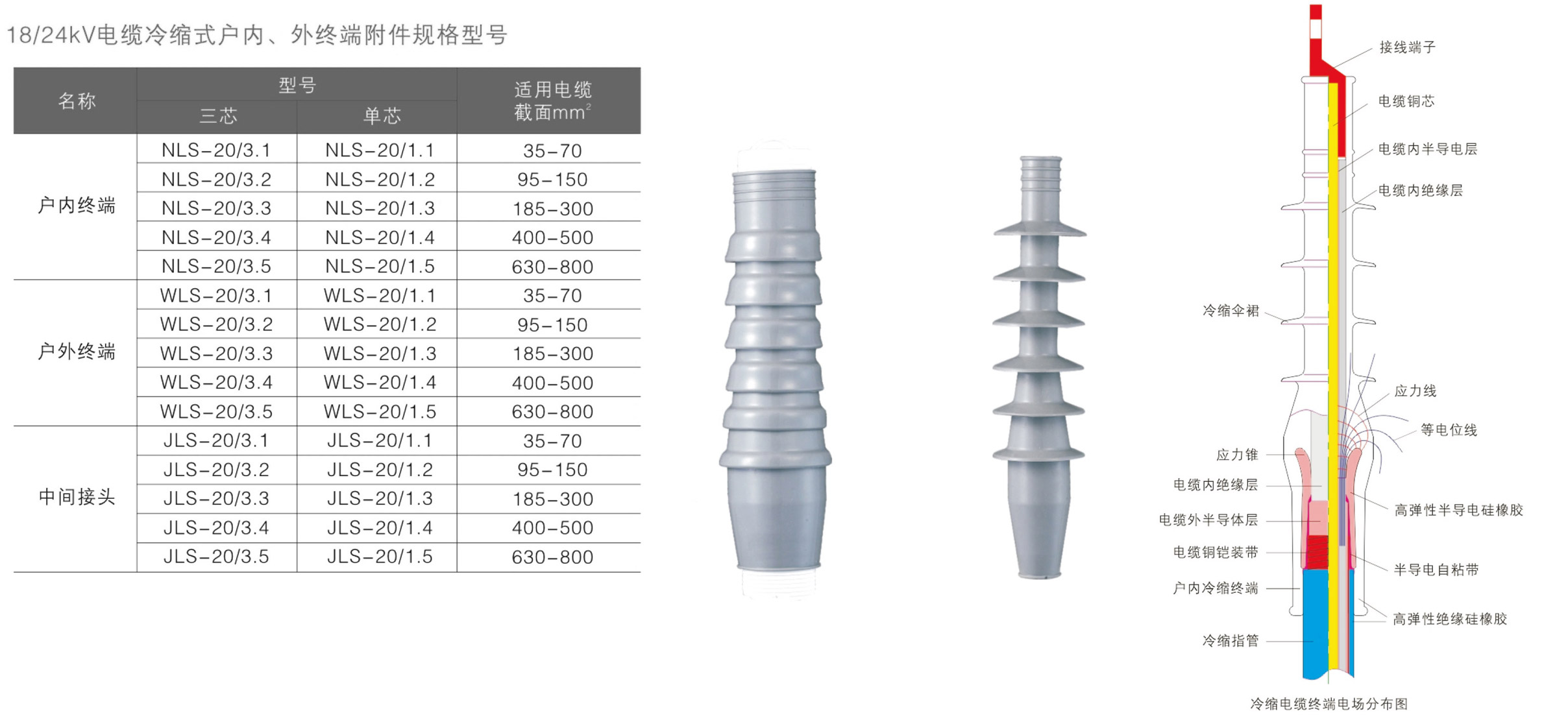

18/24kV cable cold-shrink indoor and outdoor terminal fittings

Product Model

Product Application Scope and Environment

Application Scope: 12/20kV cable cold-shrink indoor and outdoor terminal fittings, suitable for voltage level 20kV. Cable nominal cross-sectional area: 25~500mm².

Applicable Environment: The product uses imported high-elasticity special high-quality silicone rubber as the material. The pollution level reaches IV, the electric pressure control is geometric, the electrical performance is stable, and it is suitable for installation in various environments. The insulation level, current carrying capacity, long-term operating temperature, and short-circuit temperature all meet the technical requirements of the matching cable.

The product has a novel structural design, excellent performance, and convenient installation. When in use, it only needs to pull off the support to automatically shrink and reset, and it is widely used in the fields of electricity, communication, military industry, metallurgy, coal mining, petrochemical industry, etc.

Product Testing Standards

Overall Product Testing Standard: GB/T12706.4-2002 Rated voltage IkV (Um=1.2kV) to 35kV (Um=40.5kV) extruded insulated power cable fittings, Part 4: Test requirements for power cable fittings with rated voltage 6kV (Um=7.2kV) to 35kV (Um=40.5kV).

Power Frequency Withstand Voltage Test: GB/T18889-2002 stipulates that it should be carried out at room temperature.

Partial Discharge Test: GB/T18889-2002 stipulates that it should be carried out at room temperature, with a background interference of 1.8pc during the test.

Load Cycle Test: GB/T18889-2002 The conductor is heated to 95℃~100℃, and stabilized at this temperature for at least 2h: Each cycle is 8h, including 5h heating and 3h natural cooling, until the difference from the ambient temperature does not exceed 10℃.

Impulse Voltage Test: GB/T18889-2002 stipulates that it should be carried out.

Salt Spray Test: GB/T18889-2002 Chapter 13 stipulates that it should be carried out.

Humidity Test: GB/T18889-2002 Chapter 13 stipulates that it should be carried out.

Note: Unless otherwise specified, the test should be carried out at ambient temperature.

When the terminal performance is significantly degraded due to the following reasons, it is considered to be significantly damaged:

1. Degradation of dielectric quality due to leakage current traces;

2. The depth of electro-corrosion reaches 2mm or 50% of the smallest wall thickness of any insulation material used;

3. Material cracking

4. Material perforation

Product Attachments: